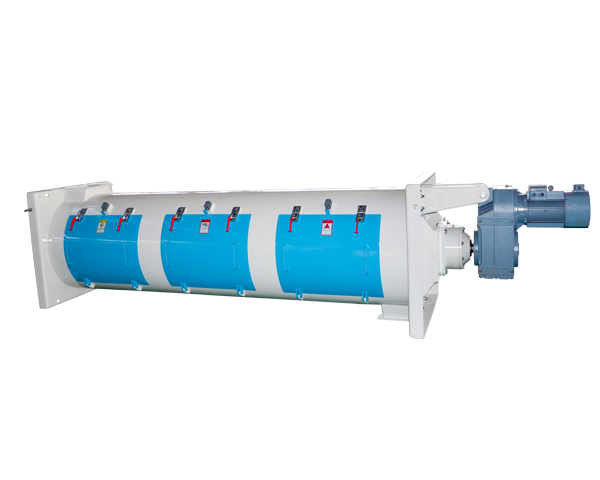

The equipment is mainly used for curing and sterilization before granulation and bulking in feed production process. By combining with other equipment such as feeding and tempering, the curing degree of materials can be greatly improved;

The equipment is mainly used for curing and sterilization before granulation and bulking in feed production process. By combining with other equipment such as feeding and tempering, the curing degree of materials can be greatly improved;

The external steam jacket or heat armour is heated,and the internal spiral blade conveys materials, which can ensure first-in first-out and reduce residue and cross-contamination.

The external steam jacket or heat armour is heated,and the internal spiral blade conveys materials, which can ensure first-in first-out and reduce residue and cross-contamination.

Hot nail heating temperature rise fast, high thermal efficiency.

Hot nail heating temperature rise fast, high thermal efficiency.

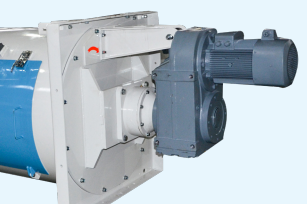

Driven by a shaft-mounted reducer,the operation is stable,and the special screed structure ensures the stable current of the pellet mill.

Driven by a shaft-mounted reducer,the operation is stable,and the special screed structure ensures the stable current of the pellet mill.

Equipped with variable frequency motor, conditioning time extends up to 3 minutes, can make the material fully cooked, optimize the pelleting process, and improve the capacity which can be increased by 10-15%.

Equipped with variable frequency motor, conditioning time extends up to 3 minutes, can make the material fully cooked, optimize the pelleting process, and improve the capacity which can be increased by 10-15%.

The conditioning temperature can reach 85-100℃(adjustable), which can improve water resistance and effectively kill African swine fever virus and Salmonella.

The conditioning temperature can reach 85-100℃(adjustable), which can improve water resistance and effectively kill African swine fever virus and Salmonella.

Special homogenizing and dispersing mechanism, stable and uniform discharge

Special homogenizing and dispersing mechanism, stable and uniform discharge

Back to list

Back to list