Recently, the first phase of the Yangzhou Jinlida high-end aquatic feed project designed, manufactured, and installed by Jiangsu Faster Machinery Co., Ltd. has successfully passed the completion acceptance. After comprehensive evaluation, the shrimp, crab, and puffed feed production line project has far exceeded national standards in terms of technical indicators, engineering quality, automation level, cleanliness and safety, energy conservation and environmental protection, and has received unanimous praise from customers.

This is another stable strategic cooperation relationship established by both parties after the cooperation with Super Keeper (Maturation Kettle), which reflects the high recognition and trust of customers for the quality of equipment and engineering in Jiangsu Fast!

Yangzhou Jinlida Feed Co., Ltd. is a member enterprise of Zhejiang Jinlida Group, located in Gaoyou City, Jiangsu Province. It was established on March 20, 2006 and integrates shrimp and crab farming, aquatic feed production, and sales. Jiangsu Dongtai is the birthplace of the "small shed shrimp farming and fast shrimp farming" model, and the characteristics of aquaculture inevitably have strict requirements for the cleanliness, safety, and traceability of aquatic feed.

Based on the positioning of Jinlida Group's high-end aquatic feed project, Faster Company has equipped host equipment that represents the current international leading and domestic first-class technological level according to the process flow of "ingredients first, then crushing, and then undergoing ultra-fine crushing and secondary ingredient mixing".

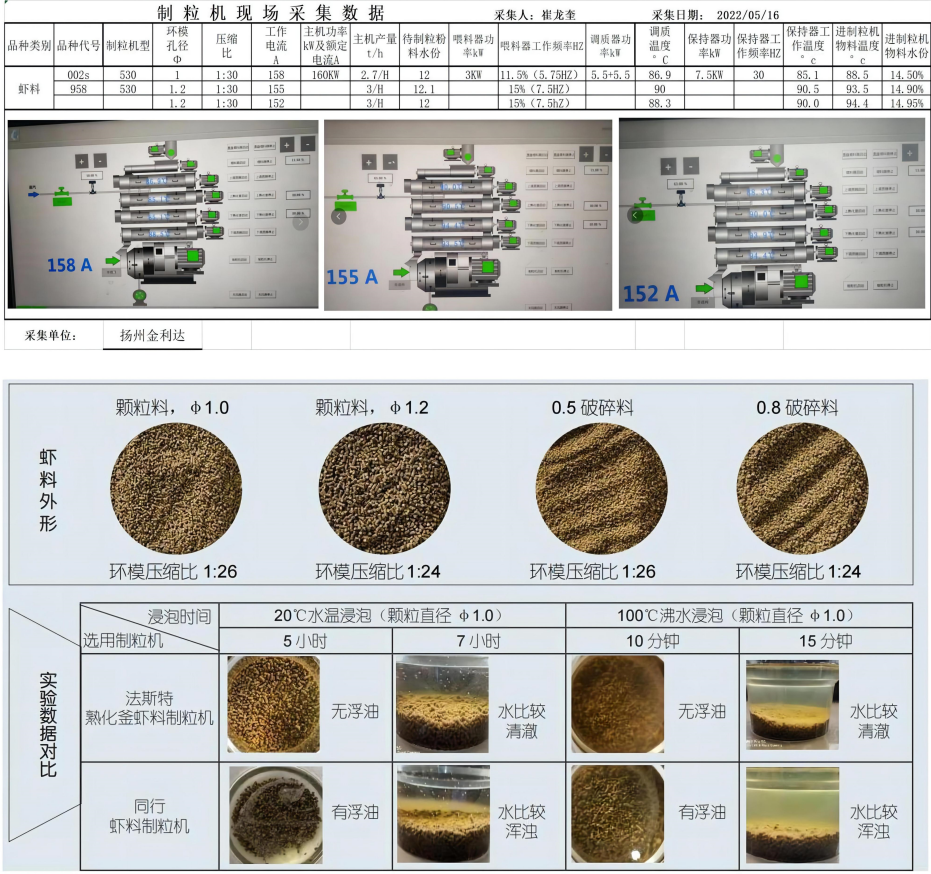

Curing kettle shrimp material granulator

The pre curing system equipped with a curing kettle (patented technology from Faster) greatly improves the curing degree and stability of granulation, with low powder content and no oil floating in the shrimp feed. The unique design of the jacket homogenizer unit and the optimized blade structure make the high humidity and high viscosity material flow more uniform, thereby making the operation of the granulator more stable. The Fast Shrimp Granulator can be combined with one or two layers of curing kettles and homogenizers to meet customer needs and tailor solutions.

Wide micro crusher

The ultra wide multi chamber structure ensures more uniform material distribution and higher crushing efficiency. The bottom of the crushing chamber is equipped with a U-shaped secondary crushing chamber, which can effectively eliminate the circulation phenomenon during the crushing process and improve the crushing capacity and fineness.

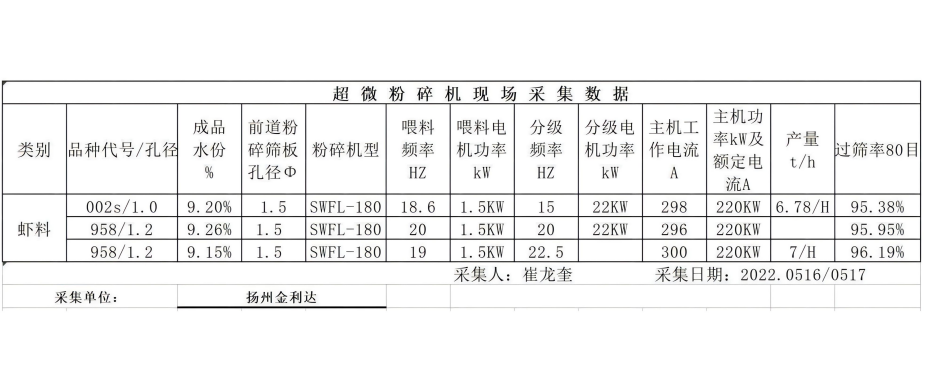

Vertical shaft ultrafine crusher

Capable of ultrafine crushing the raw materials after rough crushing, meeting the requirements for material fineness in subsequent processes. The crushing particle size is continuously adjustable from 60 to 200 mesh. The vertical shaft without screen structure makes the structure more compact, low vibration, and low noise. The unique crushing chamber structure combined with an optimized grading system effectively improves feed yield and greatly reduces energy consumption. The device with hydraulic lifting top cover can facilitate the replacement of vulnerable parts.

Double shaft paddle mixer

The classic dual axis blade structure utilizes the principle of weight loss for mixing, resulting in a short mixing cycle and high mixing uniformity. The dual output shaft gear reducer direct transmission makes the equipment operate more smoothly and can achieve load start. The gentle transmission method is particularly suitable for occasions with weighing and mixing.

Impeller cooler

Using the principle of countercurrent cooling to cool particles with high temperature and humidity can effectively prevent surface cracking of particles. Equipped with an adjustable disperser mechanism, the fabric is evenly distributed, ensuring consistent height of the material layer in the cooling bin and good cooling effect.

To ensure the high-quality and efficient progress of the project, the project always adheres to the principle of "quality first, safety first, progress first, and efficiency first". During the construction process, the process design is adjusted and optimized in a timely manner according to the on-site situation of the project, ensuring that the project can be put into operation as soon as possible and receiving praise from customers. Jiangsu Faster will continue to provide follow-up services and technical support to customers, creating more long-term value for them!

The Yangzhou Jinlida High end Aquatic Feed Project is another high-end aquatic feed complete set engineering project of Jiangsu Faster, following the complete sets of aquatic feed engineering projects of Shandong Haibo, Tongwei Group, Hengxing Group, Jiangxi Aohua, Jiangsu Heguan, etc. It marks a new level of Faster's special aquatic feed process equipment technology!