On July 1st, Guanghui Biotechnology (Shenyang) Co., Ltd. celebrated the grand opening of its factory in Shenyang, Liaoning Province, which has an annual production capacity of 500,000 tons of high-end livestock and poultry feed and 60,000 tons of premixed feed. This factory, meticulously built by Jiangsu Fast, received unanimous praise from both the owners and industry experts.

Guanghui Biotechnology (Shenyang) Co., Ltd. is a wholly-owned subsidiary of Guangying Group, located in Xinmin City, Shenyang. The project covers an area of 40 acres with a total investment of 120 million yuan. It is a group company integrating product research and development, production, sales, and service.

At the launching ceremony, leaders from Shenyang City and Xinmin City, Chairman Mu Yudong of Guangying Group and all its employees, Chairman Tang Jinxiang of Jiangsu Faster Intelligent Equipment Co., Ltd., along with many other distinguished guests and over a hundred industry elites, gathered together to witness this grand event.

In his opening speech, Chairman Mu of Guangying Group highly praised Jiangsu Fast for its excellent performance in engineering design, construction, and quality control. He expressed his firm belief that, with the latest intelligent production equipment, Shenyang Guanghui will ensure that every production order meets the highest quality standards.

Guangying Group and Jiangsu Fast have collaborated to create a feed plant with advanced process design, energy-efficient equipment, and a high degree of automation. This factory not only meets the market demand for high-quality premixed and ruminant feed but also sets a new benchmark in the industry.

The project not only incorporates advanced design concepts to optimize production processes and processing techniques to the fullest extent, but also features a complete set of high-efficiency equipment from JS Fast. The advanced processing techniques and equipment are reflected in:

One: The production lines for livestock and ruminant feed are equipped with advanced systems including rapid receiving and cleaning pulverization systems for raw material silos, high-precision computer weighing and batching systems, double shaft paddle batch-type intermittent mixing systems, Ripening kettle strong cooking conditioning granulation system, expanded and secondary granulation processes for starter feed, innovative liquid computer weighing and molasses water dilution spraying processes for ruminant feed, counterflow impeller discharge coolers, and drawer-type rotary screens, among other mature innovative products. The entire process is fully automated with computerized full-screen control, digital multimedia warning devices, and a production process quality traceability system, etc. The technical level of the project is in a leading position in China.

Direct-linking double shaft Paddle Mixer

The first domestic single motor dual gearbox hard tooth surface transmission technology, the equipment has a stronger load capacity, more uniform mixing, can add a variety of liquids and solids at the same time, spray accurately, and easy to control

Full-length fully opening door discharging, fast discharging speed, extremely low residue; silicone sealing strips are used to ensure that there is no leakage during the entire mixing process

Two: The premix production line adopts a unique additive material positive pressure dense-phase pneumatic conveying system and computer micro-scale high-precision batching technology, achieving the core elements of "clean, sanitary, residue-free, and cross-contamination-free" in the production of high-grade premix. The single-shaft high-speed paddle mixer achieves fast mixing (120 seconds/batch), high uniformity (Cv value ≤ 3%), and low residue (≤ 0.5‰). The microelement scale greatly enhances batching accuracy and efficiency. Computerized full-screen automation control, digital multimedia warning devices, and a production process quality traceability system ensure the advanced level of this premixing process and equipment domestically.

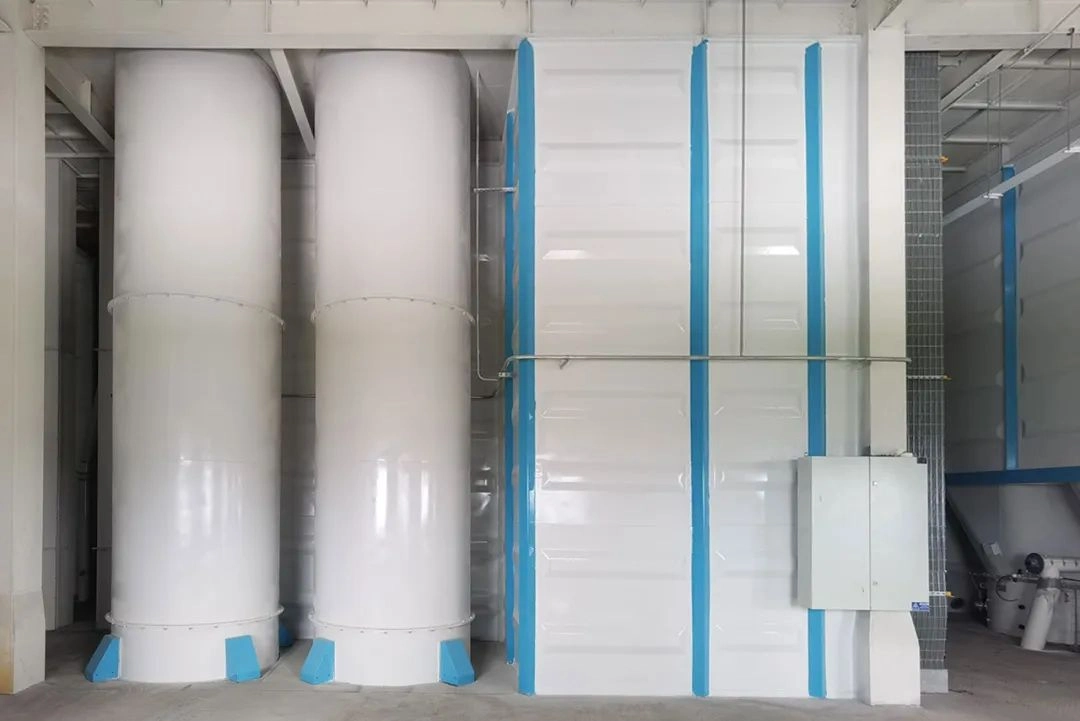

Positive pressure dense-phase pneumatic conveying pressure vessel system.

Breakthrough multiple key technological bottlenecks, improving overall efficiency and productivity.

It utilizes compressed air system for conveying, with flexible layout and no residue.

High pressure, long transmission distance, little air demand, no air leakage, small wear, lower overall operating costs

In the future, Jiangsu Fast will continue to innovate independently, adhere to more advanced, stable and reliable equipment, tailor unique processes for customers, ensure the quality of customers' products, and meet the needs of farmers for high-end, green and safe feed!