◆ It has 3 utility model patents and 1 appearance patent ◆

Laying hens are an important poultry in China. In 2023, the total number of laying hens in China is 1.02 billion, and the annual per capita consumption of eggs is 20.8kg, ranking tenth in the world.

China has the largest number of laying hens in the world. It is a big country of laying hens, but it is not a strong country of laying hens. In particular, the feed quality of laying hens is uneven, and the processing technology and equipment of laying hens are relatively backward.

China has the largest number of laying hens in the world. It is a big laying hen country, but it is not a strong laying hen country. In particular, the quality of laying hen feed is uneven, and the laying hen feed processing technology and equipment are relatively backward.

First, the pain points of laying hens feed

The first major pain point of laying hen feed is-high powder content, especially high powder content after corn grinding, the general powder content is 18-25% (calculated by the proportion of 18-mesh under the sieve), the second is the "Unevenness in Particle Size Distribution" of crushed corn, which will bring the following problems:

1, The feed trough is not cleaned thoroughly, making feed prone to spoilage, especially during the summer;

2, Feed wastage due to dust during production, transportation, and feeding processes:

3, Laying hens are prone to "respiratory diseases":

4, High maize content in feed leads to "fatty liver" disease in laying hens:

5, "Feeding lines" are prone to blockages:

6, Segregation of particles and powders is common in feed.

Second, the advantages of Fast special crusher for laying hens

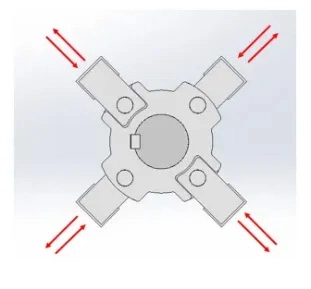

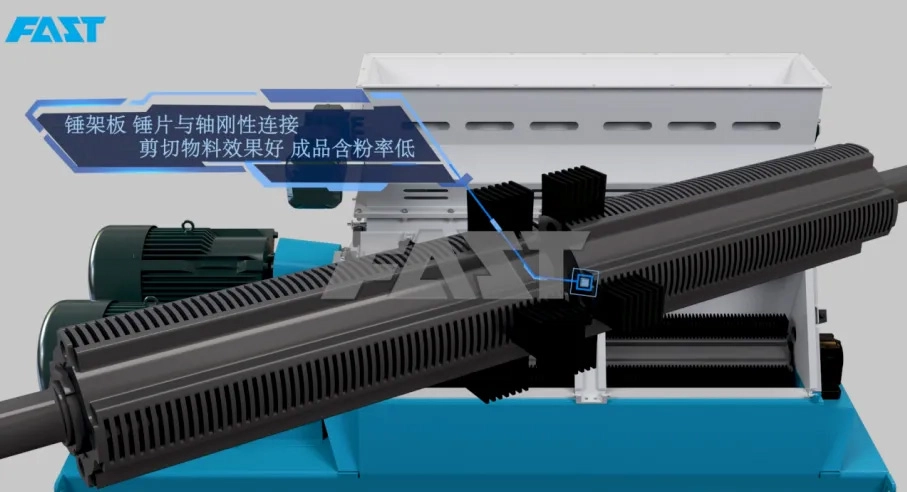

Jiangsu Fast has done a lot of market research, and through the research of grinding technology, the development of SDFP series of layer feed shredder. The basic principle of the shredder is to maximize the use of the shear force of crushing, using the low-speed rotation of the fixed hammer blade, the corn is cut out at the fastest speed, and the corn is only cut 1-2 times, so the excessive crushing phenomenon is very rare, and the finished product has low powder content and high output.

◆ Fixed hammer and knife structure, good shear effect, corn finished 18 mesh under the screen less than 9%;

◆ Heavy frame, low center of gravity design, more stable operation;

◆ The hammer blade adopts the insert structure, the three points are firmly positioned, the replacement is fast, convenient and safer;

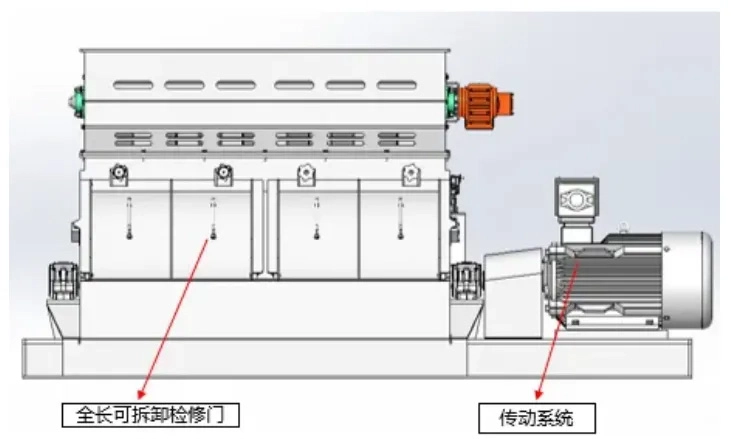

◆ Full-open movable gravity door, screen plate replacement operation space, more convenient maintenance;

◆ Screen plate is fixed by bolts, no need to press screen mechanism, can accurately ensure the hammer screen clearance.

Third, the main structure of the laying hen hammer mill

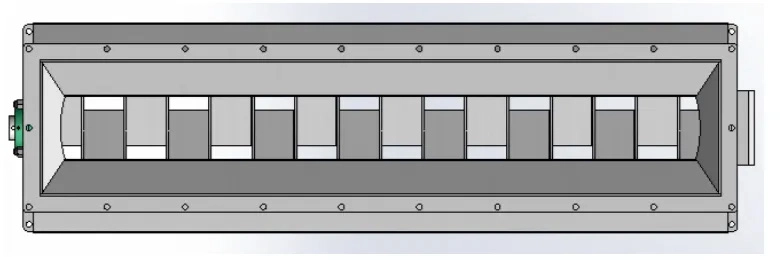

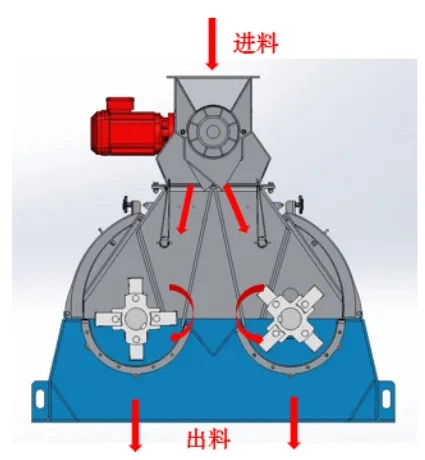

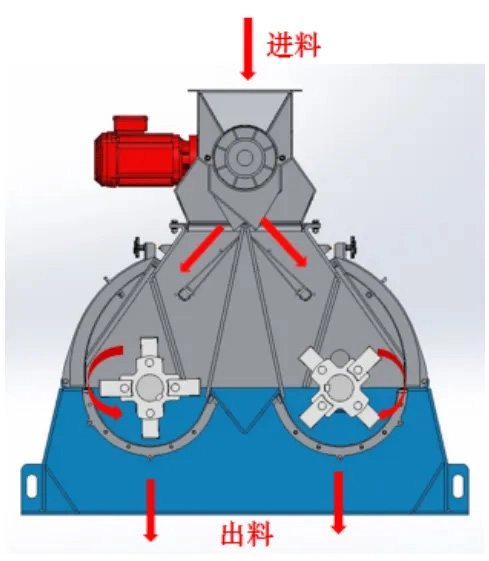

1, The staggered arrangement of material mechanisms ensures uniform feeding.

The feeder adopts full-length impeller feeding, controlled by variable frequency, ensuring uniform feeding; staggered arrangement of material mechanisms ensures consistent feeding and load between the two rotors.

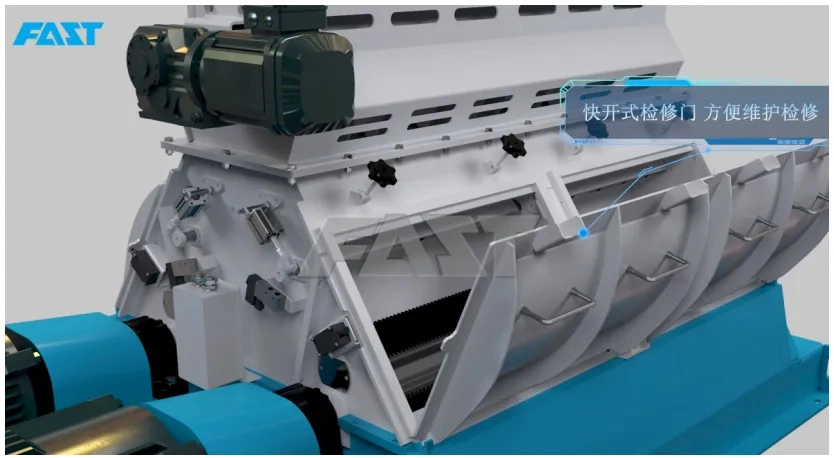

2, Full-open movable gravity door, screen plate replacement operation space, more convenient maintenance;

3, Hammer blade quick insert installation, easy to replace

The hammer and the main shaft are rigidly connected through the hammer frame plate, using a quick-insertion fixing method, which makes maintenance and replacement more convenient and efficient.

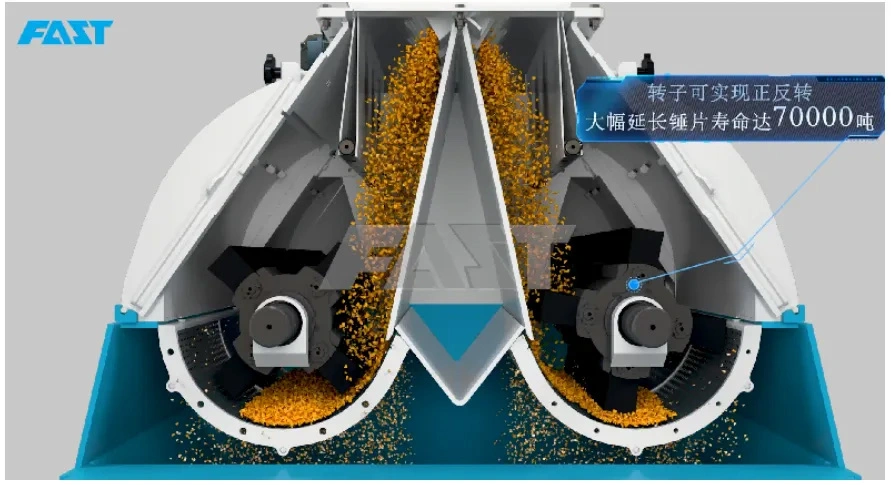

4, Hammer blades have a long lifespan

The shearing force is the main force between the hammer blade and the corn, which has low wear and high efficiency. One set of hammer blades can crush 70,000 tons of corn (7 mm sieve aperture).

5.Working principle

The corn enters the grinding chamber along the tangential direction and at low speed through the impeller feeder, and passes through the sieve screen after shearing with the hammer blade to form the pulverized finished product with low powder content and uniform particle size distribution.

Rotor forward grinding diagram

↑ Rotor reverse crushing diagram ↑

6, Finished crushed corn

Forth, Model specification table

<img src="/ueditor/php/upload/image/20240412/1712886599903556.webp" alt="Model specification table/>

Fifth, Cooperate with customers and use empirical data

1, Guangxi Liyuan Group

2, Shanxi Elephant Group

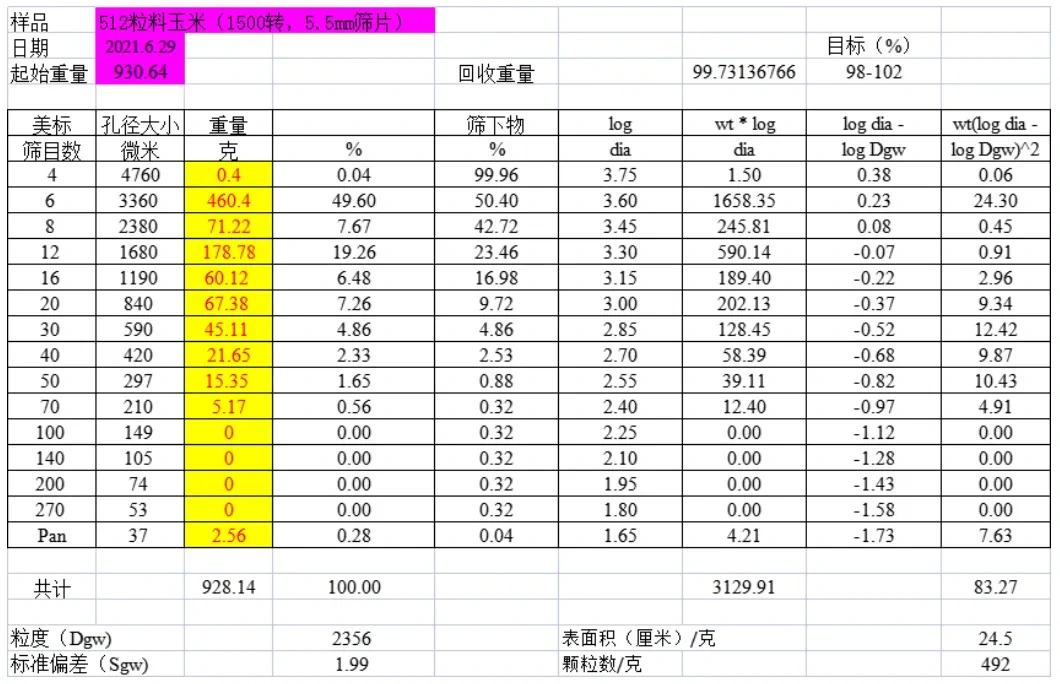

3, Daxiang Group test report (finished crushed corn) :

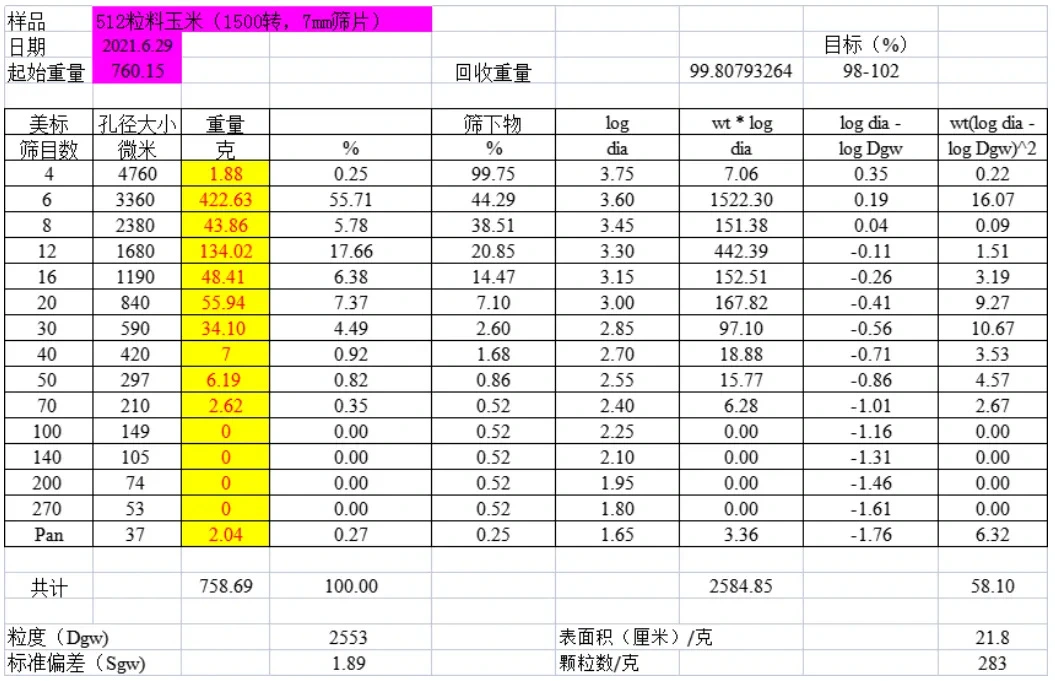

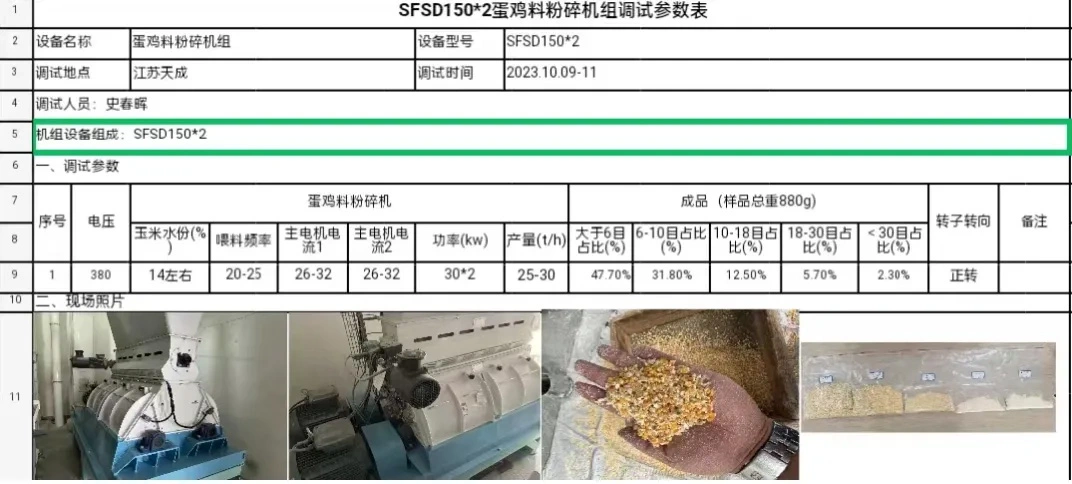

3. Jiangsu Tiancheng Group

Jiangsu Tiancheng commissioning data report (finished crushed corn) :

4. Shaanxi Shiyang Group

↓ Production scene video ↓

5, Yunnan Kaiyuan Yongxing Breeding Company (300,000 modern laying hen farm)

6, Yunnan Jianshui Chunxiao Breeding Company (300,000 modern laying hen farm)

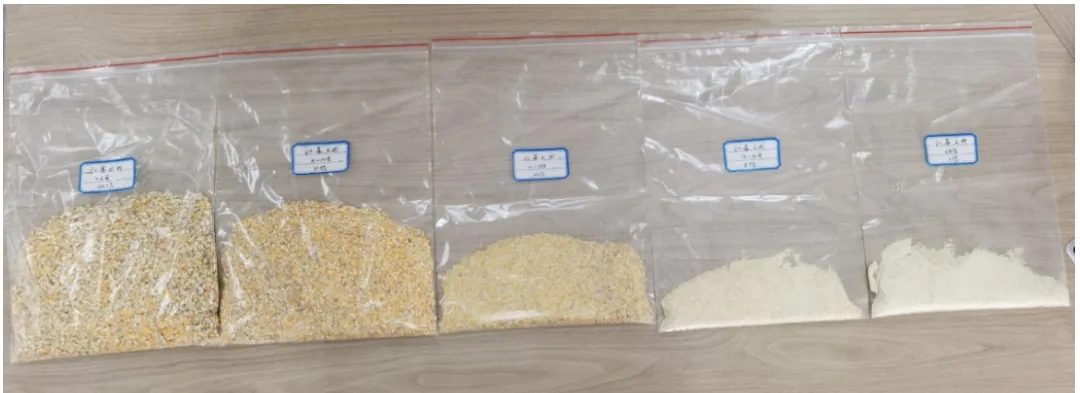

Jianshui Chunxiao Breeding company's finished laying hen material:

↑ Finished Laying hen Feed ↑

"Loading of bulk laying hen feed-dust-free"

Six, the value of creation

1, Reducing waste in laying hen feed, calculated at a waste rate of 0.5%, you can save 500 tons out of every 100,000 tons of laying hen feed. With the cost of laying hen feed estimated at 2500 yuan per ton, this amounts to a yearly savings of 1.25 million yuan!

2, Reducing illness in layers, at a cost of 2 yuan per chicken, with 100,000 chickens, you can save 200,000 yuan!

3, Reducing malfunctions in the automatic feeding line.

4, Ensuring a balanced feed intake for laying hens.

5, Making the layers coop cleaner and more sanitary.

◆ Innovation is the gene of Fast ◆

◆ Producing valuable products is the cornerstone of FAST's service to global customers. ◆