"Fields of golden rice ripple like waves, with abundant fruits perfuming the air for miles around.", in this golden autumn October, spring and autumn days, we are full of joy, welcome the harvest! On October 22, 2023, the complete set of high-grade aquatic feed projects of Jingzhou Baiyang Feed Co., Ltd. built by Jiangsu Fast ushered in the completion and acceptance of the project.

Yang Sihua, deputy general manager of Baiyang Stock, Director Qin Yansong, Director of production center, Deputy Director Ji Nature, Project manager Li Xuean, Deputy general Manager Gao Yi of Jingzhou Baiyang Feed Co., LTD., General manager Tang Jinxiang of Jiangsu Fast Machinery Co., LTD., Director Chen Dongjie of technology center, Deputy Director Wang Fei of Engineering Center, etc., participated in the project completion acceptance ceremony. During the whole process of the project from contract signing to project implementation, commissioning and operation, many leaders of Baiyang and Fast received care and support, and gave valuable guidance in the process layout, equipment selection and commissioning control of the project, laying a solid foundation for the smooth acceptance of the project.

The specialized aquatic feed factory built by Jingzhou Baiyang and Jiangsu Fast is designed with four production lines, which are: one production line of 10 tons of expanded feed, one production line of 5 tons of expanded feed (reserved), two production lines of 8-10 tons of crayfish and high-grade fish feed pellets (reserved); At present, the two production lines of the first phase have been successfully put into operation and passed the test of the production season, and the production and quality control indicators have met the requirements of the contract. After detailed evaluation and review, the representatives of both sides agreed that the project has the advantages of advanced technology, stable and reliable equipment, high degree of automation, environmental protection and low carbon. In particular, the ripening degree and appearance of crayfish pellet feed have led the peers and been loved by customers, so the representatives of both sides agreed that the project successfully passed the acceptance! With the smooth operation of the project, we firmly believe that Jingzhou Baiyang will be able to provide higher quality aquatic feed for farmers in Central China, and at the same time lay a solid foundation and build strong confidence for Baiyang's strategic goal of focusing on Central China and expanding the national market!

Workshop on-site acceptance scene

The representatives of both parties review and sign the acceptance form

Ⅰ. Features of the main equipment

1. Double shaft blade mixer

(1). Double output shaft hard gear reducer direct transmission, smooth operation, high reliability;

(2). Full-length large door unloading mode, fast unloading speed, low residue;

(3). Using the classic double shaft blade structure and the principle of weightlessness, the mixing period is short and the uniformity is high;

(4). Various liquids can be added in the mixing process, which is precise and easy to add.

2. Ripening kettle shrimp pellet mill

(1). The pellet mill adopts belt flexible transmission, stable operation, reliable, high output;

(2). Used with ripening kettle and tempering system, high curing degree, strong water resistance;

(3). The ripening kettle is triple-heated by hollow paddle, hollow spindle and jacket, which integrates the functions of heating, cooking and sterilization. The cooking degree of shrimp stock reaches more than 45%, the pellet content is low, and the appearance is moist;

(4). Automatic lubrication system, eliminating oil cut-offs.

Ripening kettle - shrimp pellet mill

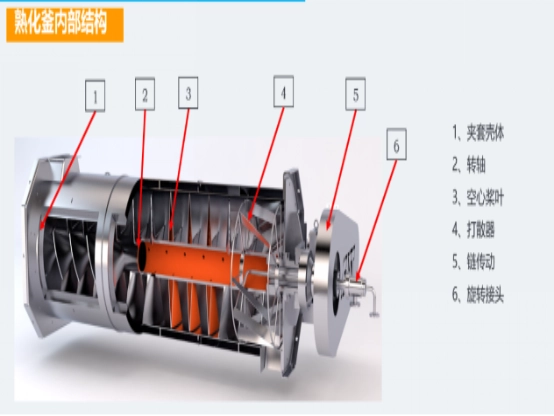

3. SSHF Series Ripening Kettle

(1). Ripening kettle is a patented product invented by Fast, which can be called the aquatic product cooking artifact!

(2). The casing is a jacket, the central shaft and blade are hollow design, the use of special rotary joint dynamic sealing technology, the production of the shell jacket, the central shaft and blade respectively into the steam, compared with the traditional retainer, its heating area increased by 3 times;

(3). It can quickly heat up the feed to more than 95℃, single-layer curing time 6-8 minutes, multiple curing POTS superposition and shrimp granulation unit, so that the curing degree of aquatic pellets can reach more than 45%, and the pellet section is flat, and the powder content is low;

(4). The shrimp ripening kettle has been widely used by Haibo Group, Tongwei Group, Hengxing Group, Baiyang Group, Haid Group, etc., and has achieved excellent efficacy.

SSHF series ripening kettle

Internal structure of SSHF series cooking kettle

4. FEXD158 * 2 double screw extrusion machine

(1). Adopting modular design, through different screw combination meet different formula feed production, and with screw hydraulic ejection device, change the screw configuration convenient;

(2). The high degree of automation, friendly operation interface, greatly reduce the difficulty of the operation and maintenance,

(3). Density control instrument configuration, flexible production to sinking feed;

(4). The screw, a screw manufacturing using special wear-resistant materials and advanced processing technology, significantly improve the service life, reduce the cost;

(5). Configuration frequency 315 kW motor, make the production more flexible and convenient;

(6). Special curing pot conditioning process, puffing particle uniformity, whether in production, energy consumption exceeded the design requirements.

FEXD158*2 twin-screw extruder installation scene

5. FDRD series horizontal dryer

(1). Modular design, flexible process combination, convenient installation and transportation

(2). Internal circulation hot air system, heat exchanger built-in, low energy consumption, high drying efficiency;

(3). Interactive air chamber, balanced airflow distribution, good moisture uniformity of finished products

(4). The cloth is uniform, the Teflon screen is coated with non-stick material, the finished water is uniform, and the range is small.

(5). High degree of automatic control, easy operation and maintenance;

(6). According to the production field test data, the production capacity and energy consumption are in line with the design parameters.

According to the production field test data, the production capacity and energy consumption are in line with the design parameters.

Installation scenario of FDRD series horizontal dryer

6. SFJHc Series Drawer Rotary Sieve

(1). Drawer type screen frame design, easy to complete screen replacement;

(2). ROSTA metal elastic support, long service life, more stable operation;

(3). Discharge port front, installation, maintenance is simple and fast.

Ⅱ. Engineering installation details

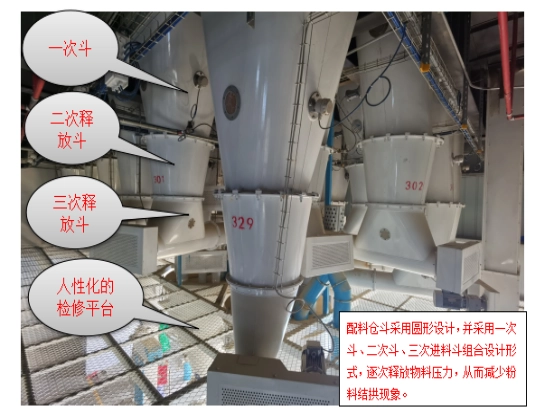

Self-reinforcing welding chamber (Eliminate the phenomenon of bolt hanging in the assembly bin)

Batching bin installation details

Final product bin hopper installation details

Distributor and slide pipe installation scene

Tubular screw conveyor, high batching precision, low residue, reduce cross contamination

Ingredients scale and small ingredient feeding station installation scene

Fine Grinding Hammer Mill installation scene

Ultrafine pulverizer installation scene

Ultrafine pulverizer air mesh system installation scene

Swing cooler installation scene

Grease adding system installation scene

High temperature and high humidity pulse jet dust collector installation scene

Full screen control system scene

Robotic palletizing system

A glimpse of the finished product warehouse

Jiangsu Fast will continue to uphold the core values of "integrity, dedication, innovation and efficiency", provide customers with more excellent feed machinery products and services, create value for customers, and become a trusted enterprise in the industry!