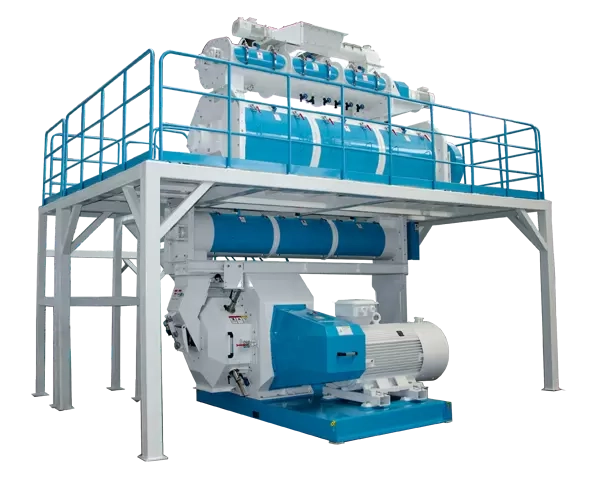

A pellet mill is a commonly used industrial equipment used to process raw materials into granular finished products. Its structural composition is very complex, including multiple components and mechanical principles. In this article, we will delve into the structural components of the pellet mill to better understand this important device.

First, let's take a look at the main components of the pellet mill. Pellet mill usually consists of several parts such as feeding system, pressing system, transmission system, cooling system and control system. Each part has its own unique function and importance, and they work together to enable the pellet mill to efficiently complete the task of pellet production.

The feeding system is the first part of the pellet mill, which is responsible for transporting raw materials to the interior of the pellet mill for processing. The feeding system usually includes equipment such as feeders, conveyor belts and vibrating feeders, whose function is to uniformly transport raw materials into the pellet mill's pressing system. The key to this step is to ensure the uniformity and stability of the raw materials so that subsequent processing can proceed smoothly.

The pressing system is the core part of the pellet mill, which includes components such as molds, pressure rollers, pressure wheels and pressure regulating devices. In this part, the raw materials go through a series of extrusion and pressing processes to finally form the desired granular finished product. The mold is a key component in determining the shape and size of the pellets, while the pressure rollers and rollers are responsible for applying pressure to tightly combine the raw materials. The design and adjustment of the pressing system have a direct impact on the production efficiency and finished product quality of the pellet mill, so its structure and working principle need to be carefully designed and optimized.

The transmission system is the power source of the pellet mill, which includes motors, reducers, belt drives, bearings and other components. The function of the transmission system is to convert electrical energy into mechanical energy and transfer it to the pressing system to drive the normal operation of the pellet mill. As the core component of the transmission system, the motor's power and speed directly affect the production capacity and stability of the pellet mill. The reducer and belt drive play the role of transmitting and regulating power, ensuring the coordinated operation of the various components of the pellet mill.

The cooling system is an important auxiliary part of the pellet mill, which includes equipment such as coolers, fans and conveying devices. During the pellet mill production process, since extrusion and pressing will generate heat in the raw materials, it needs to be dissipated through a cooling system to ensure the quality and stability of the finished pellets. The cooler usually uses water circulation or air cooling to quickly take away the heat, while the fan plays the role of heat dissipation and ventilation to keep the temperature and humidity inside the pellet mill within a suitable range.

The control system is the intelligent part of the pellet mill, which includes PLC controllers, touch screen operation panels, sensors and other equipment. The function of the control system is to monitor and adjust the operating status of the pellet mill to achieve automated production and intelligent management. As the core component of the control system, the PLC controller achieves precise control and coordinated operation of each component of the pellet mill through programming and logic control. The touch screen operation panel provides operators with an intuitive interface and convenient operation methods, while the sensors are responsible for monitoring various parameters and status of the pellet mill and providing timely feedback to the control system to achieve real-time monitoring and adjustment of the pellet mill.

To sum up, the structure of the pellet mill is very complex, including the feeding system, pressing system, transmission system, cooling system and control system. Each part has its own unique function and importance, and they work together to efficiently complete the task of pellet production. By having an in-depth understanding of the structural composition of pellet mills, we can better understand its working principles and production processes, and provide more comprehensive and in-depth guidance for the use and maintenance of pellet mills.

Pellet mill: essential equipment to improve feed quality

Why pellet mills require regular maintenance

How to choose a quality pellet mill manufacturer

Pellet mill maintenance and upkeep: the key to extending equipment life

Ensure safety and master the operating skills and precautions of pellet mill

Explore the different types of pellet mills and their applications

How to choose the right pellet mill to improve production efficiency