As people's demand for healthy food continues to increase, the poultry breeding industry has also developed rapidly. As an important part of poultry breeding, poultry feed's production efficiency is crucial to the development of the breeding industry. This article will discuss the production efficiency of poultry feed production lines and explore how to improve production efficiency to meet market demand.

Poultry feed production lines refer to production lines that process raw materials into feed suitable for poultry through a series of processing steps. It mainly includes raw material cleaning, crushing, mixing, granulation, drying, packaging and other links. The design and operation of production lines are crucial to improving production efficiency.

Raw material cleaning is the first process in the poultry feed production line, and its purpose is to remove impurities and substandard substances in the raw materials. Improving raw material cleaning efficiency can be achieved through the following aspects:

1. Optimize cleaning equipment: Using advanced cleaning equipment, such as magnetic separators, vibrating screens, etc., can clean raw materials more quickly and thoroughly and improve cleaning efficiency.

2. Automated control: The introduction of automated control systems can realize intelligent control of cleaning equipment, improve cleaning efficiency, and reduce manual operations.

Crushing is the process of pulverizing the cleaned raw materials. The purpose is to make the raw material particles smaller to facilitate subsequent mixing and granulation. Improving crushing efficiency can be achieved through the following aspects:

1. Select suitable crushing equipment: Select suitable crushing equipment according to the characteristics of the raw materials, such as jaw crusher, hammer crusher, etc., to complete the crushing work more efficiently.

2. Control the crushing particle size: Reasonably control the discharge particle size of the crushing equipment to avoid over-crushing or under-crushing to improve crushing efficiency.

Mixing is a process of uniformly mixing the crushed raw materials. Its purpose is to fully mix various raw materials to ensure the balance of the feed. Improving mixing efficiency can be achieved through the following aspects:

1. Optimize mixing equipment: Choose efficient mixing equipment, such as double screw mixers, double cone mixers, etc., to complete the mixing work faster and more uniformly.

2. Control the mixing time: Reasonably control the mixing time of the mixing equipment to avoid being too long or too short to improve mixing efficiency.

Pelletization is a process of shaping the mixed raw materials. Its purpose is to make the feed into granules for easy consumption by poultry. Improving granulation efficiency can be achieved through the following aspects:

1. Optimize granulation equipment: Choose efficient granulation equipment, such as flat die granulators, ring die granulators, etc., to complete the granulation work faster and more stably.

2. Control the granulation humidity: Reasonably control the humidity of the raw materials to avoid being too wet or too dry to improve the granulation efficiency.

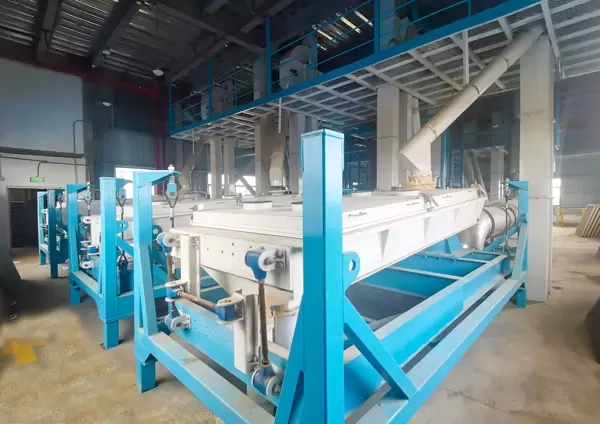

Drying is the process of dehydrating the pelleted feed. Its purpose is to reduce the humidity of the feed and improve its preservation. Improving drying efficiency can be achieved through the following aspects:

1. Optimize drying equipment: Choose efficient drying equipment, such as fluidized bed dryers, belt dryers, etc., to complete the drying work faster and more thoroughly.

2. Control the drying temperature: Reasonably control the temperature of the drying equipment to avoid being too high or too low to improve drying efficiency.

Packaging is the process of packaging dried feed. Its purpose is to protect the quality and hygiene of the feed. Improving packaging efficiency can be achieved through the following aspects:

1. Optimize packaging equipment: Choose efficient packaging equipment, such as automatic packaging machines, sealing machines, etc., to complete packaging work faster and more accurately.

2. Control packaging speed: Reasonably control the speed of packaging equipment to avoid being too fast or too slow to improve packaging efficiency.

The production efficiency of poultry feed production lines is crucial to the development of the breeding industry. By optimizing raw material cleaning, crushing, mixing, granulation, drying and packaging, production efficiency can be effectively improved and market demand can be met. At the same time, the introduction of advanced equipment and automated control systems can further improve production efficiency and realize the intelligence and automation of feed production.

As a poultry feed production lines manufacturer, FAST is committed to producing and selling high-quality poultry feed production lines. Our products cover all aspects of feed production, including raw material processing, crushing, mixing, granulation, cooling, screening, Packaging etc. We have advanced production equipment and technical teams, able to provide customized solutions to meet the needs of different customers. Whether you are a feed manufacturer or feed processor, we can provide you with feed production lines solutions to help you achieve business growth and success.