Feed grinder is one of the commonly used equipment in animal husbandry. Its main function is to crush feed raw materials to improve the digestibility and utilization rate of feed. However, many farmers often encounter inefficiency when using feed grinders, which affects production benefits. This article will explore how to improve the efficiency of feed grinders from multiple aspects.

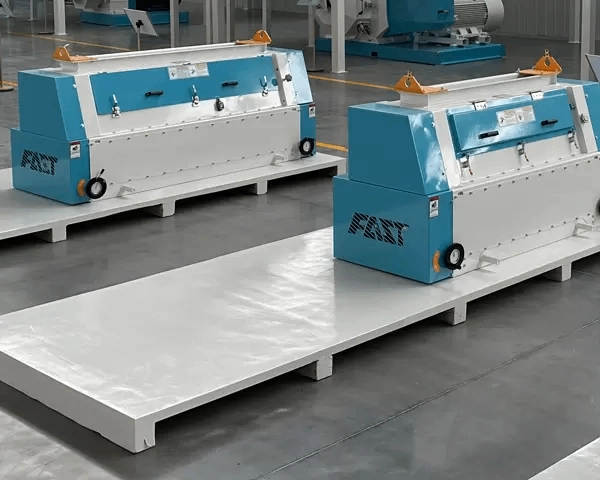

First, choosing a suitable feed grinder is the key to improving efficiency. The model and specifications of the feed grinder should be selected according to production needs and raw material characteristics. Generally speaking, for larger-scale farms, large feed grinders should be selected to meet the needs of large amounts of feed. For small farms, small feed grinders can be selected to save costs and space. In addition, the quality of the feed grinder is also an important factor affecting efficiency, and products with reliable quality and stable performance should be selected.

Secondly, reasonably adjust the working parameters of the feed grinder. The working parameters of the feed grinder include feed speed, rotation speed, and screen aperture. Too fast feed speed will cause equipment blockage, and too slow feed speed will reduce production efficiency. Therefore, the feed speed should be reasonably adjusted according to the characteristics of the raw materials and the performance of the equipment. The rotation speed is an important parameter that affects the crushing effect. Too high a rotation speed will lead to uneven feed crushing, while too low a rotation speed will reduce the crushing efficiency. The selection of the screen aperture should be determined according to the required feed particle size. Too small an aperture will cause equipment clogging, while too large an aperture will affect the crushing effect. Therefore, these parameters should be reasonably adjusted according to the actual situation to improve the efficiency of the feed grinder.

In addition, keeping the feed grinder in good condition is also the key to improving efficiency. Regularly perform equipment maintenance, clean up the accumulated materials and debris inside the equipment, check whether the various parts of the equipment are operating normally, and replace worn parts in time to ensure the normal operation of the equipment. At the same time, pay attention to the lubrication and cooling of the equipment to ensure that the equipment can operate normally under high temperature and high load. In addition, the equipment should be regularly inspected and adjusted to ensure the crushing effect and work efficiency of the equipment.

In addition, the reasonable selection of feed raw materials can also improve the efficiency of the feed grinder. The particle size and humidity of feed raw materials are important factors affecting the crushing effect. Generally speaking, the particle size of feed raw materials should be moderate. Too large particles will affect the crushing effect, and too small particles will increase energy consumption. The humidity of feed raw materials should also be moderate. Too high humidity will cause equipment clogging, and too low humidity will reduce the crushing effect. Therefore, appropriate feed raw materials should be selected according to actual conditions to improve the efficiency of feed grinders.

Finally, reasonable arrangement of production plans and operating procedures is also an important factor in improving the efficiency of feed grinders. The production plan should be reasonably arranged according to production needs and equipment performance to avoid idling and idleness of equipment and improve the utilization rate of equipment. At the same time, operators should be trained to ensure that they are proficient in the operation skills and safe operating procedures of the equipment to improve work efficiency and ensure production safety.

In summary, improving the efficiency of feed grinders requires consideration from multiple aspects. Choosing appropriate equipment, reasonably adjusting working parameters, maintaining the good condition of equipment, reasonably selecting feed raw materials, and reasonably arranging production plans and operating procedures are all the keys to improving the efficiency of feed grinders. Only by doing a good job in these aspects can the efficiency of feed grinders be improved and the production benefits of the breeding industry be improved.

As a feed grinder manufacturer, we are committed to providing high-quality and efficient grinder equipment to meet customer needs. We not only focus on product performance and reliability, but also focus on innovation and technological progress to continuously optimize our products.