In modern livestock farming, feed mixer is one of the indispensable and important equipment. It can evenly mix various feed raw materials to ensure balanced nutrition for animals, thereby improving breeding efficiency and animal health. Horizontal feed mixer has become the preferred equipment for many farms due to its compact structure, uniform mixing and convenient operation. However, facing the wide variety of horizontal feed mixers on the market, how to choose a device that suits your needs? This article will analyze it in detail from multiple angles.

Before purchasing horizontal feed mixers, you must first clarify your needs. Different breeding scales and feed types have different requirements for mixers, so you need to choose according to actual conditions.

The breeding scale is an important reference factor for choosing a mixer. Small farms usually only need to process a small amount of feed, so they can choose a mixer with a smaller capacity; while large farms need to process a large amount of feed, so they need to choose equipment with a larger capacity. Generally speaking, the capacity of the mixer ranges from hundreds of liters to thousands of liters, and users should choose the appropriate capacity according to their own breeding scale.

Different feed types have different requirements for mixers. For example, dry feed and wet feed are mixed differently. Dry feed usually requires stronger stirring force, while wet feed requires better sealing to prevent water loss. In addition, if the feed contains more fiber materials (such as silage), a mixer with stronger cutting function needs to be selected.

After clarifying the needs, the core performance indicators of the mixer need to be paid attention to, which directly affect the use effect and life of the equipment.

Mixing efficiency is one of the important indicators for measuring the performance of the mixer. An efficient mixer can mix the feed evenly in a shorter time, thereby improving production efficiency. The mixing efficiency is usually related to factors such as the mixer speed, the shape and number of mixing blades. Generally speaking, the higher the speed, the higher the mixing efficiency, but too high a speed may cause the feed to be over-mixed, affecting the quality of the feed.

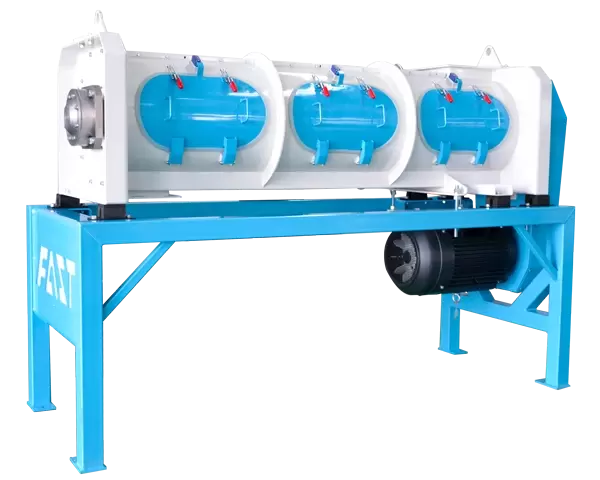

Mixing uniformity is another important indicator for measuring the performance of the mixer. Uniform mixing can ensure that the animal's intake of nutrients is balanced, thereby improving the breeding effect. Mixing uniformity is related to factors such as the design structure of the mixer and the arrangement of the mixing blades. Horizontal mixers usually use double helical mixing blades, which can achieve better mixing effects.

The power configuration directly affects the working efficiency and energy consumption of the mixer. Generally speaking, the power sources of mixers are electric motors and diesel engines. Electric motors are suitable for places with stable power supply, while diesel engines are suitable for places with unstable power supply. Users should choose the appropriate power configuration according to their actual situation.

The material of the mixer directly affects the service life of the equipment and the safety of the feed. High-quality mixers are usually made of stainless steel or high-strength alloy steel, which has good corrosion resistance and wear resistance. In addition, the sealing of the equipment is also an important consideration. Good sealing can prevent the feed from being contaminated during the mixing process.

In addition to the core performance indicators, the functional design of the mixer is also an important factor to consider when choosing. Good functional design can improve the operating convenience and maintenance efficiency of the equipment.

With the development of science and technology, more and more mixers are equipped with automatic control systems. Mixers with a high degree of automation can realize functions such as automatic feeding, automatic mixing, and automatic unloading, which greatly reduces the labor intensity of manual operation. For large farms, choosing a mixer with a high degree of automation can significantly improve production efficiency.

The design of the operation interface directly affects the user experience of the equipment. A good operation interface should be concise and easy to operate. Some premium mixers are also equipped with a touch screen control system, through which users can easily set the mixing parameters and monitor the operating status of the equipment in real time.

The mixer needs regular maintenance during use, so maintenance convenience is also an important consideration. A good maintenance design should include easily removable mixing blades, convenient lubrication systems, etc. In addition, the cleanliness of the equipment is also an important consideration. A good cleaning design can reduce feed residues and prevent bacterial growth.

When purchasing a horizontal feed mixer, brand and after-sales service are also important factors that cannot be ignored. High-quality brands usually have a good market reputation and high user satisfaction, and can provide reliable equipment and perfect after-sales service.

Choosing a mixer from a well-known brand can guarantee the quality and performance of the equipment to a certain extent. Well-known brands usually have a long market history and more user feedback. Users can understand the brand's reputation by checking user reviews and consulting industry experts.

After-sales service is an important factor to consider when choosing a mixer. High-quality after-sales service can provide users with timely technical support, equipment maintenance and spare parts supply services to ensure the long-term and stable operation of the equipment. When choosing a mixer, users should understand the supplier's after-sales service policy and choose a supplier that can provide perfect after-sales service.

Finally, economic efficiency is also an important factor to consider when choosing horizontal feed mixers. Users should comprehensively consider the price and use cost of the equipment on the premise of ensuring the performance and quality of the equipment, and choose equipment with high cost performance.

Equipment price is one of the first factors that users consider when choosing a mixer. The prices of horizontal feed mixers of different brands and models vary greatly. Users should choose suitable equipment according to their budget. It should be noted that price is not the only consideration. Users should comprehensively consider factors such as equipment performance, quality, and after-sales service to choose equipment with high cost performance.

The use cost includes the energy consumption, maintenance costs, and parts replacement costs of the equipment. When choosing a mixer, users should comprehensively consider the cost of using the equipment and choose equipment with low energy consumption, convenient maintenance and reasonably priced accessories.

Choosing a suitable horizontal feed mixer requires comprehensive consideration of multiple factors, including breeding scale, feed type, mixing efficiency, mixing uniformity, power configuration, equipment material, degree of automation, operating interface, maintenance convenience, brand reputation, after-sales service, equipment price and use cost, etc. Users should choose equipment with superior performance, reliable quality and high cost performance according to their actual needs, combined with market research and user feedback. Through reasonable selection and use, the horizontal feed mixer will become an important tool to improve breeding efficiency and animal health.