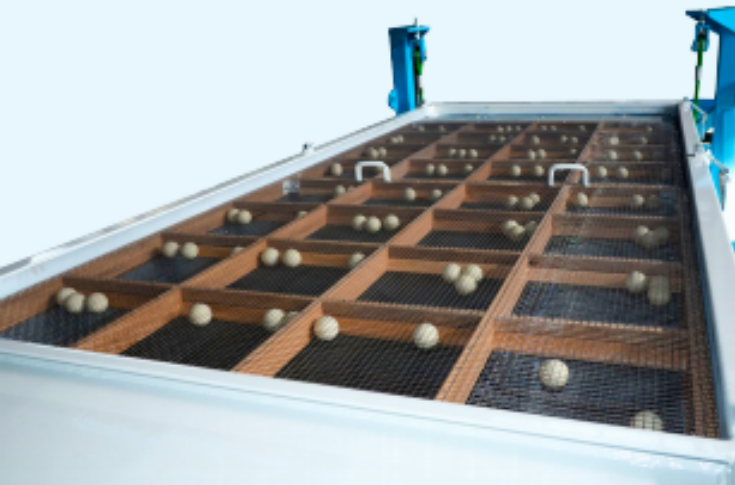

Through the vibration of the screen, the mixture of different particle sizes is graded according to the particle size, and the unqualified small particles or powder are sifted out and re-pelleting;

Through the vibration of the screen, the mixture of different particle sizes is graded according to the particle size, and the unqualified small particles or powder are sifted out and re-pelleting;

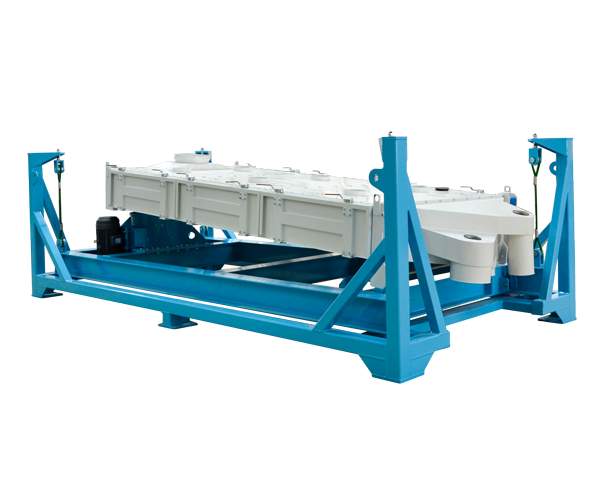

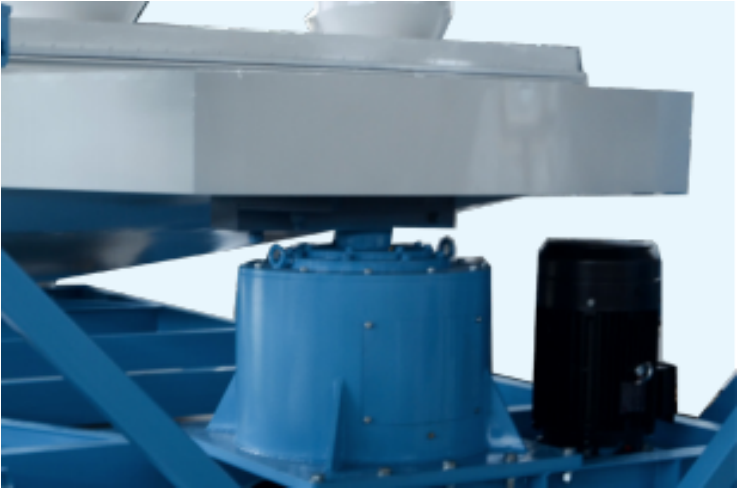

The screen body is driven by self-balancing vibration mode, so that the screen body produces a certain amplitude and vibration frequency, the sifting effect is good, and the size is small, the performance is stable, and the application is wide;

The screen body is driven by self-balancing vibration mode, so that the screen body produces a certain amplitude and vibration frequency, the sifting effect is good, and the size is small, the performance is stable, and the application is wide;

A soft connection is adopted between the feed inlet and the chute. Through the separator, the material is dispersed and then falls into the screen surface. The material is further dispersed on the baffle to enter the first screen surface in a uniform state;

A soft connection is adopted between the feed inlet and the chute. Through the separator, the material is dispersed and then falls into the screen surface. The material is further dispersed on the baffle to enter the first screen surface in a uniform state;

The screen frame is an integral structure made of welded steel plates to ensure sufficient strength under higher frequency vibration and reduce noise caused by vibration;

The screen frame is an integral structure made of welded steel plates to ensure sufficient strength under higher frequency vibration and reduce noise caused by vibration;

The sieve frame is symmetrically mounted on four hollow rubber springs on the frame to form a multi-directional free vibration system;

The sieve frame is symmetrically mounted on four hollow rubber springs on the frame to form a multi-directional free vibration system;

The rubber spring can support the screen frame so that the screen body has the required running trajectory; At the same time, absorbing the kinetic energy generated by the vibration of the screen body.

The rubber spring can support the screen frame so that the screen body has the required running trajectory; At the same time, absorbing the kinetic energy generated by the vibration of the screen body.

Back to list

Back to list