Feed pellet mill is an indispensable equipment in modern livestock breeding industry. It can process raw materials into high-quality pellet feed and improve the feed utilization rate and production performance of animals. Raw material pretreatment is a key step in the feed pellet mill production process, which directly affects pellet quality and production efficiency. This article will delve into the raw material pretreatment of feed pellet mills, as well as methods and techniques on how to improve pellet quality through pretreatment.

Raw material pretreatment is the primary link in the production process of feed pellet mill. Its purpose is to conduct preliminary processing of raw materials in order to better adapt to the processing requirements of the pellet mill. The importance of raw material pretreatment is mainly reflected in the following aspects:

Improve pellet quality: Through raw material pretreatment, impurities, foreign matter and indigestible substances in the raw material can be removed, reducing clogging and failure of the pellet machine, thereby improving pellet quality and consistency.

Improve production efficiency: Raw material pretreatment condition and homogenize the pellet size, humidity and density of raw materials, making the processing process of the pellet machine more stable and efficient, and improving production efficiency.

Reduce energy consumption and costs: Through raw material pretreatment, the energy consumption and wear of the feed pellet mill can be reduced, the service life of feed pellet mills can be extended, and production costs and maintenance expenses can be reduced.

Cleaning and sieving: Clean and screen the raw materials to remove impurities, foreign matter and indigestible substances. Cleaning equipment and sieving machinery, such as tube magnet , drum sieve, oscillation sieve , etc., can be used to ensure the purity and quality of raw materials.

Grinding and crushing: For raw materials with excessively large or hard pellets, grinding and crushing are required to better adapt to the processing requirements of the granulator. Equipment such as grinders and crushers can be used to break the raw materials into appropriate pelle sizes.

Conditioning and homogenization: Carry out appropriate humidity and temperature adjustment according to the humidity and temperature requirements of the raw materials. Steam, hot air, etc. can be used to adjust the humidity and temperature of the raw materials to a suitable range to improve the processing effect of the pellet machine and the quality of the pellets.

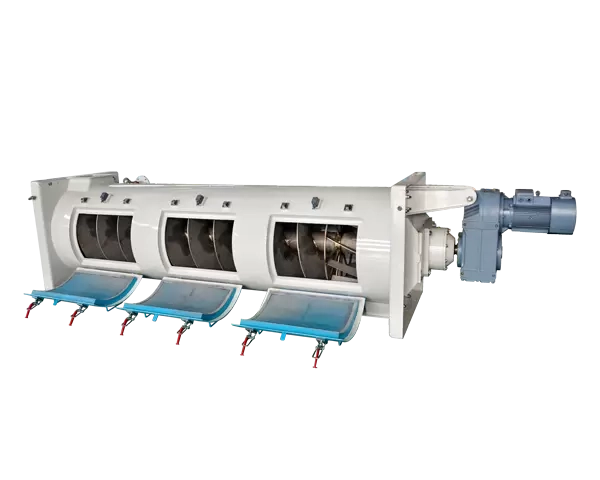

Mixing and batching: For the mixing and batching of multiple raw materials, appropriate mixing and stirring processes are required to ensure the uniformity and consistency of the raw materials. Mixers, blenders and other equipment can be used to fully mix and stir the raw materials.

Extruding and fermentation: For certain raw materials, such as corn, soybeans, etc., puffing and fermentation can be performed to improve the digestibility and feed value of the raw materials. Extruders, fermentation tanks and other equipment can be used to properly expand and ferment the raw materials.

According to the characteristics of raw materials and processing requirements, select appropriate pretreatment methods and equipment to ensure that the pretreatment effect and processing effect match.

Control the humidity and temperature of raw materials to avoid the impact of too high or too low on the pellet machine, and pay attention to moisture and mildew prevention.

Pay attention to the preservation and storage of raw materials to avoid moisture, deterioration and pollution, which will affect the pellet quality and production results.

Regularly inspect and maintain pretreatment equipment to maintain normal operation and service life of the equipment.

Raw material pretreatment is an indispensable link in the production process of feed pellet mill, which directly affects pellet quality and production efficiency. Through pretreatment methods and techniques such as cleaning, sieving, grinding, conditioning, homogenization, mixing, batching, extrudig and fermentation, pellet quality can be improved, production efficiency can be improved, and energy consumption and costs can be reduced. When preprocessing raw materials, you need to pay attention to selecting appropriate methods and equipment, controlling humidity and temperature, paying attention to preservation and storage, and regularly inspecting and maintaining equipment. Only by doing good pretreatment of raw materials can we produce high-quality pellet feed and improve the efficiency and sustainable development of animal husbandry.