In today's agricultural production, feed is an important material basis for the development of animal husbandry, and its quality is directly related to the output and quality of livestock products. With the advancement of science and technology, the technology of feed production lines has been continuously innovated, which has provided the possibility of improving feed quality. This article aims to analyze how the technological progress of feed production lines affects feed quality.

In recent years, feed production lines have undergone a transformation from manual workshop production to automated and intelligent production. Modern feed production lines use advanced computer control systems, precise batching equipment, efficient mixing machinery and strict quality inspection processes. The use of these technologies has greatly improved production efficiency, and at the same time played a key role in the quality stability and safety of feed.

Improvement of batching accuracy: Modern feed production lines are equipped with automatic batching systems, which can accurately put raw materials according to formula requirements, and the error is controlled within a very small range. Data show that the batching error of production lines using automatic batching systems can be as low as 0.1%, which is much lower than the 5% error rate of traditional manual batching. This improvement in accuracy ensures that the proportion of various nutrients in the feed is more scientific, which helps the balanced intake of animals.

Improved mixing uniformity: The mixing uniformity of feed is another key factor affecting feed quality. By using a three-dimensional mixer or a twin-shaft paddle mixer, the feed production line can achieve efficient mixing and fully integrate various raw materials. Experimental data show that modern mixing equipment can achieve a mixing uniformity of more than 98% in a short time, while traditional mixing methods are only about 80%.

Control and monitoring of the production process: Modern feed production lines have introduced real-time monitoring and quality control systems. Through sensors and monitoring software, key parameters in the production process, such as temperature, humidity, pressure, etc., can be monitored in real time to ensure the stability of the production process. For example, improper temperature control will affect the stability of vitamins in feed, while modern production lines can accurately control temperature fluctuations within ±1°C, effectively ensuring the stability of nutrients.

Quality assurance of finished products: At the end of the feed production line, there is a strict quality inspection link. By sampling and testing the finished feed, including nutrient analysis, microbial testing, etc., it is ensured that each batch of feed meets the standards. According to statistics, the qualified rate of products of enterprises using modern production lines is as high as 99.9%, which is significantly better than traditional production methods.

In summary, the technological progress of feed production lines has a significant effect on improving feed quality. From precise ingredients, efficient mixing, strict production control to quality inspection of finished products, the technological improvement of each link provides a strong guarantee for the optimization of feed quality. In the future, with the continuous advancement and innovation of technology, the feed production line will be more intelligent and automated, contributing more to the sustainable development of animal husbandry.

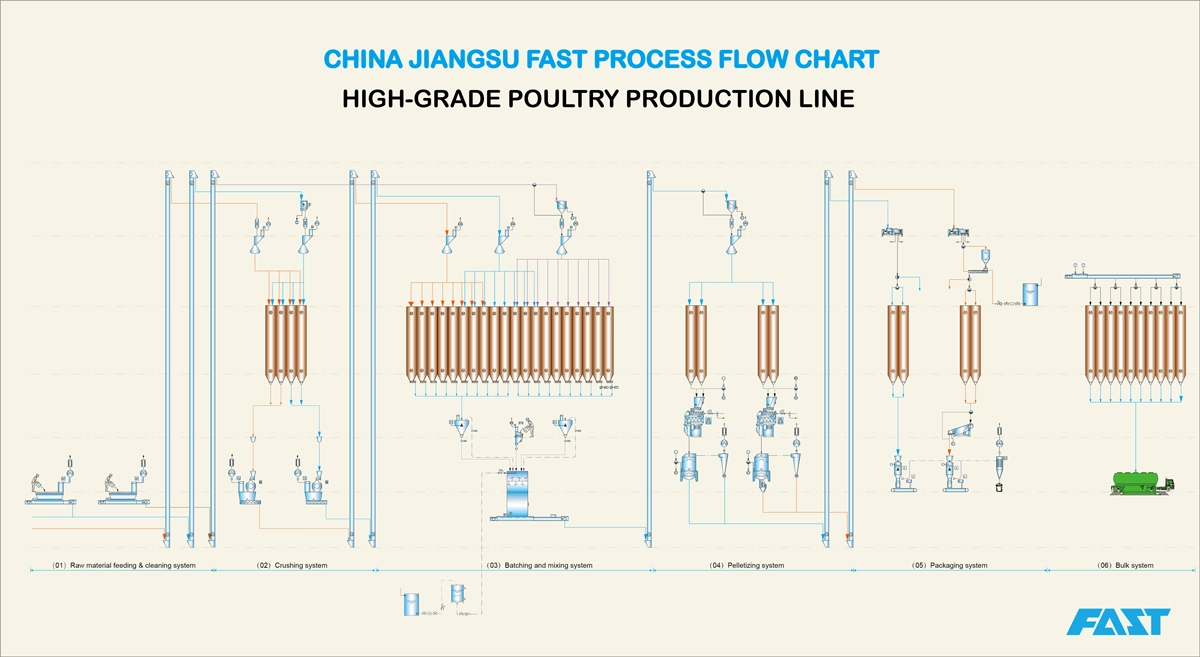

As a feed production line supplier, we have advanced technology and equipment to provide efficient feed production lines. Every link from raw material processing to finished product packaging has been carefully designed and optimized. Our production line is highly automated and intelligent, which can achieve a fast, accurate and reliable production process, provide customers with high-quality, efficient and reliable solutions, help them improve production efficiency and competitiveness, and contribute to the development of the feed industry.