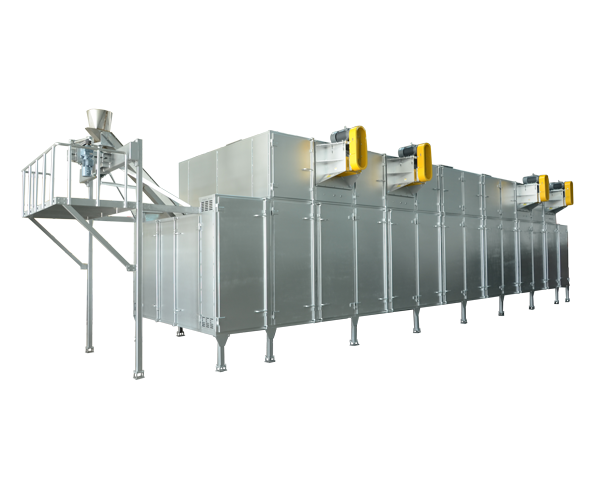

The dryer adopts frequency conversion control, which can adjust the residence time of materials in the equipment according to needs, which is easy to control the temperature rise and output of materials, and adjust the heating and curing effect of materials.

The dryer adopts frequency conversion control, which can adjust the residence time of materials in the equipment according to needs, which is easy to control the temperature rise and output of materials, and adjust the heating and curing effect of materials.

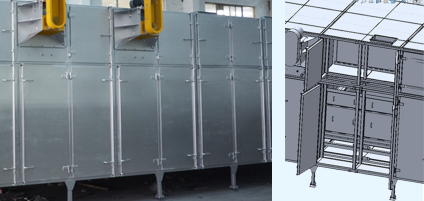

The drier adopts a detachable upper cover, and the quick-opening access door is opened on the upper cover, which is easy to clean and maintain.

The drier adopts a detachable upper cover, and the quick-opening access door is opened on the upper cover, which is easy to clean and maintain.

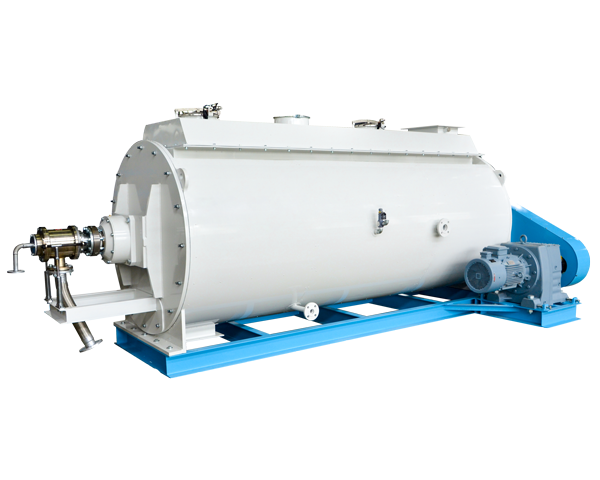

The shell of the equipment adopts jacket structure, the shell and the main shaft can be heated by steam at the same time, and the outer layer is insulated by aluminum silicate. The steam of the main shaft can be connected with the hollow heating disc through the intake pipe, so that the material can be heated evenly, the heat exchange area is large, and the effect is good.

The shell of the equipment adopts jacket structure, the shell and the main shaft can be heated by steam at the same time, and the outer layer is insulated by aluminum silicate. The steam of the main shaft can be connected with the hollow heating disc through the intake pipe, so that the material can be heated evenly, the heat exchange area is large, and the effect is good.

The material driven by the blade can be transported forward and raised upward, fully in contact with the housing, heating disc and spindle, and the heating efficiency is optimized;

The material driven by the blade can be transported forward and raised upward, fully in contact with the housing, heating disc and spindle, and the heating efficiency is optimized;

Shell, heating plate and other stainless steel production.

Shell, heating plate and other stainless steel production.

Frequency conversion control, wide range of application, high output.

Frequency conversion control, wide range of application, high output.

Back to list

Back to list